Automatic 1.8KW Inline Capping Machine SUS304 Bottle Capping Machine

Product structure and working principle:

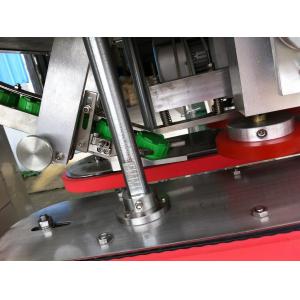

1. The product is mainly composed of cover adjusting device, slide cover groove and cover device, jia ping belt, cap wheel, lifting system, electrical control box and electrical operation panel and rack and other components.

2. Richard GaiQi slip cover cap into the slot, using centrifugal force to eliminate the above the slip cover slot cover, the slip to the set of GaiQi, conveyor belt to a bottle or jar matchs outside the machine, by the clamp clamp bottle bottle or jar, don't let its rotation to set GaiQi take cover, take cover after bottles or cans to the screw cap wheel, wheel using friction by the size of the cover cap rotates, and tighten.

Technical parameters:

| Machine model | FXZ-6L |

| Color | Gray |

| Material | SUS304 |

| Screw cap ability | 6000bottles/hour(frequency control) |

| Total Power | 1.8kw |

| Electrical Brand | Cylinder------Air TAC |

Applications:

1. This capping machine can be used for automatic capping and sealing of beverage bottles.

2. It is also suitable for some oil bottles, such as edible oil bottles, olive oil bottles, etc

3. Daily care products, such as hair shampoo, dishwashing liquid bottles are also applicable

4. Bottles of all shapes and sizes can be adapted.

Elements brands list:

Automatic 1.8KW Inline Capping Machine SUS304 Bottle Capping Machine

Competitive Advantage:

- Control interface -- the traditional control panel knob control, simple operation interface, safe and reliable;

- Electrical components -- international famous brands are adopted to ensure the safety, reliability and accuracy of the equipment;

- Mechanical parts - transmission gear belt and bottle conveyor belt are made of Italian McGowdy, the rest of the machine parts are made of 304 stainless steel.

- Function expansion -- can be configured according to customer's special requirements, such as: scanning code elimination device can be added.

What services can Changzhou Xianfei Packing Equipment Technology Co., Ltd. provide for you?

1. Product inspection

We have our own factory and quality control department, and we will check carefully to ensure the quality of the products before sending them to our customers

2. Sample services

We can send you a video of the machine in action.Welcome to visit our company and have a look at the machines being produced in our factory

3. Customization services

A: We can customize the machine according to the mechanical power, materials and bottles you provide

B: We can also offer you some professional advice on machinery.As you know, we have been in the machinery business for 16 years.

4. About install

We can provide installation.There are two options.

The first option: We can send our engineers to your company for debugging and maintenance, and your company will bear the cost of air ticket, visa, accommodation, labor and other expenses for this trip.

Option 2: Offer an online service.